About Us

Allen Tool Phoenix Inc. is a top quality precision machine shop located in East Syracuse, New York. We specialize in Close Tolerance Machining, serving Aerospace, Defense and Commercial markets. We are an AS9100D / ISO 9001:2015 Certified, Women-Owned Small Business (WOSB). We service NAICS Codes: 332710, 332721, 332992, 332993, and 332999.

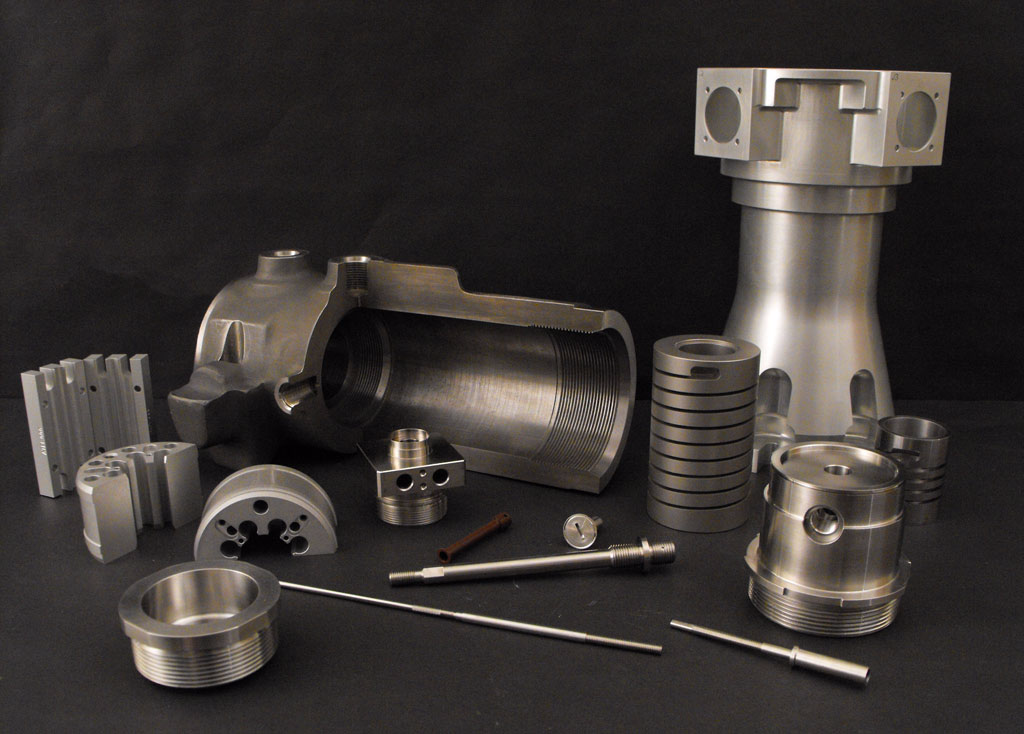

Various parts used in the refurbishment of nuclear power plants for Naval ships. Materials range from plastic, to aluminum, to steel, to high temperature alloys like inconel.

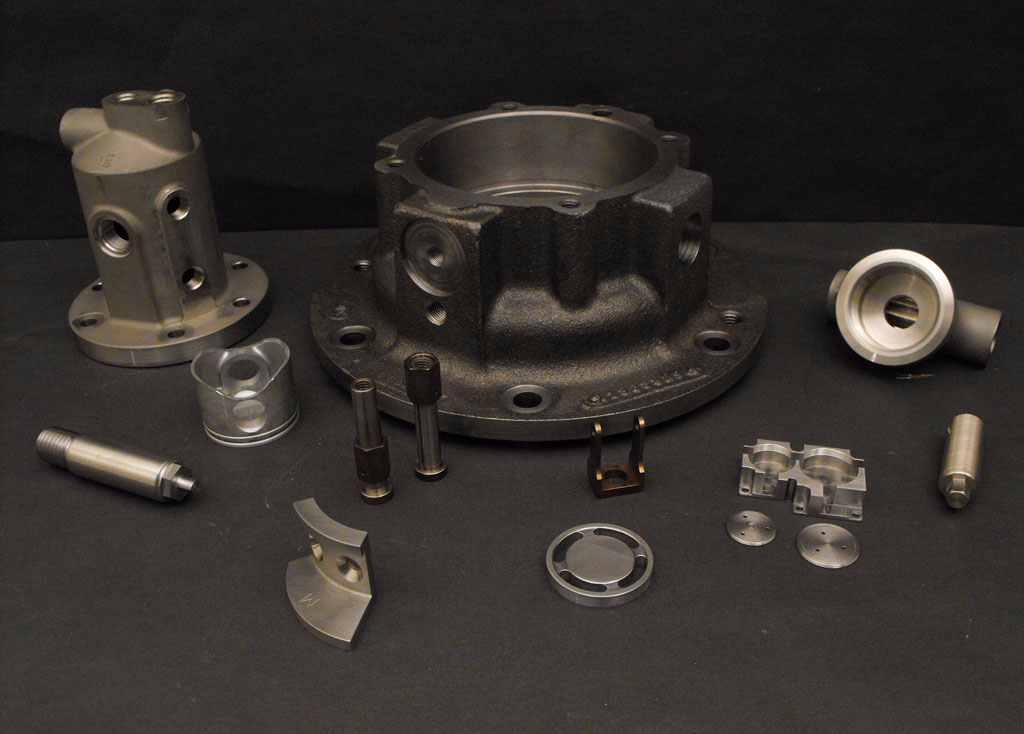

Allen Tool Phoenix supports the D.O.D by supplying munitions hardware, detonation devices, and ground troop hardware. Materials used: Various Aluminum including forgings, Maraging 250, 316 Stainless Steel, and 15-5 ph.

Allen Tool Phoenix has manufactured parts for various space flight programs. Some programs we support are the Orion and CST-100 Programs as well as Boeing’s Delta IV launch vehicles, NASA’s Ares I-X test rocket, space shuttle booster manifolds, blast shields, RL-10 Rocket Engine and stage separation components. Materials used: 7075 Aluminum, 13-8 ph, 347 stainless steel, Inconel 718.

Various machine components used in sanitizing, dosing, and bottling medicines.

Jobs that Allen Tool Phoenix considers commercial require the same precision and quality as any other industry we serve, but the procedure to track material certification, outside services, and quality control plans are less stringent. We often assist our commercial customers with design modifications and manufacturing consulting for cost-savings. Materials range from common structural steel to high temp alloys.

Allen Tool Phoenix built its reputation on manufacturing parts for the RL-10 rocket engine. The picture above shows fuel delivery pump housings and a gimbal used for maneuvering orbiting satellites. The housings on the left and right were machined out of solid aluminum billets and more impressively, using manual machines. The knowledge and experience from the employees that manufactured these parts were passed down through the ranks and is a major part of the success of Allen Tool Phoenix today.