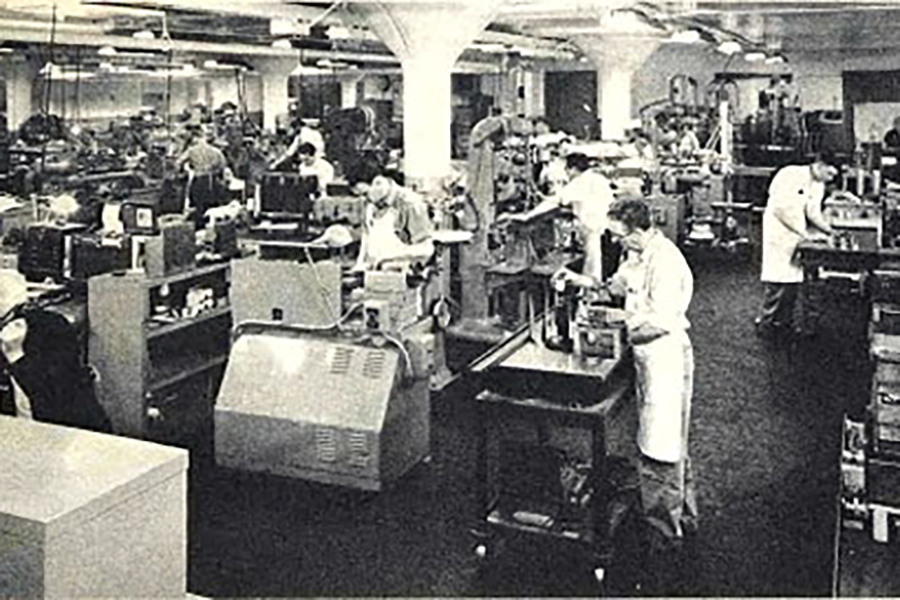

Over 30 Years of Crafting Excellence in Precision Machining

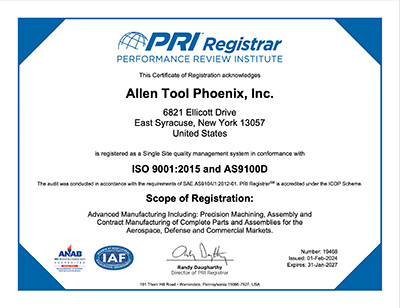

Allen Tool is a premium quality precision machining company located in East Syracuse, New York specializing in close tolerance machining for the aerospace, defense, commercial, and pharmaceutical industries. With a 99.9% quality score, we prioritize quality above all else because we know that the parts we produce will be used in critical applications.

At Allen Tool, we pride ourselves in our strong customer relationships, and respond to all customer inquiries within 1-2 days because we understand how important your time is. We continually seek new innovations in precision machining, and invest in advanced technology so that you receive cutting-edge products that exceed expectations.