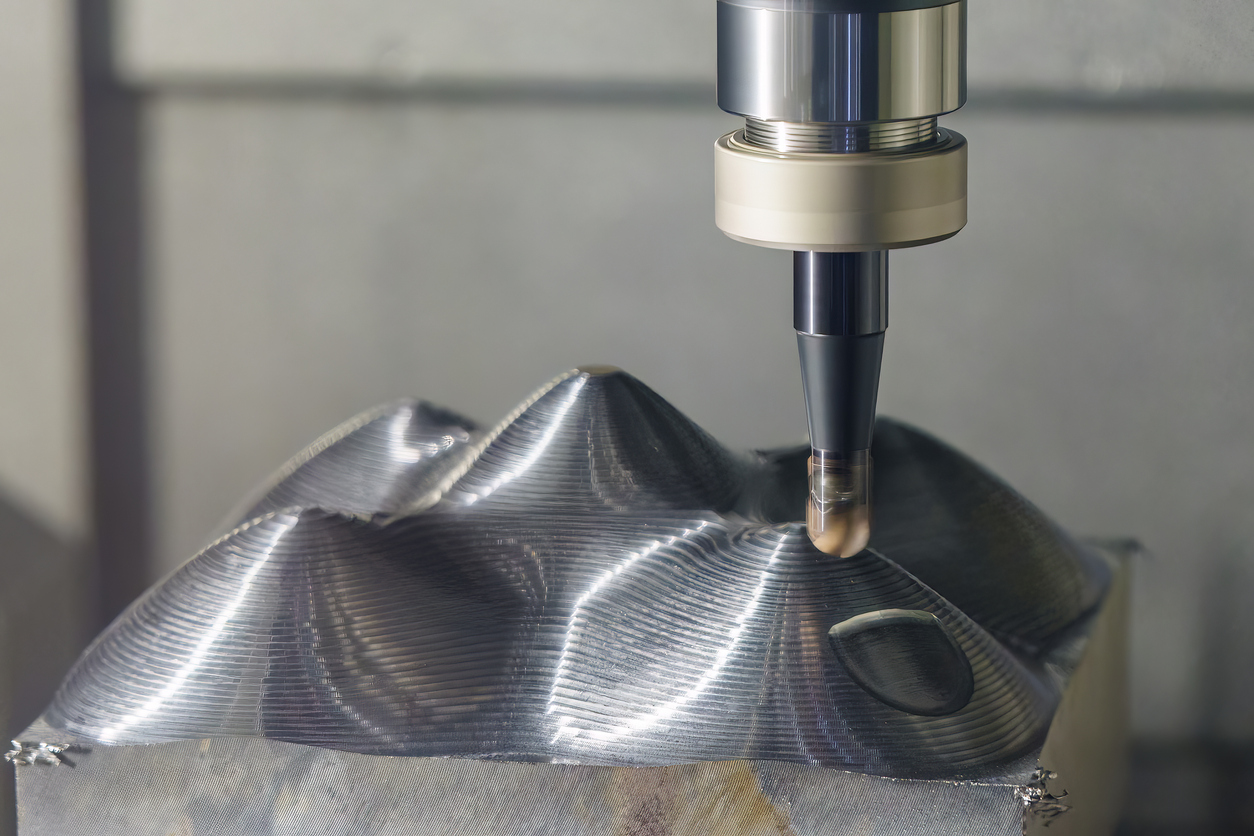

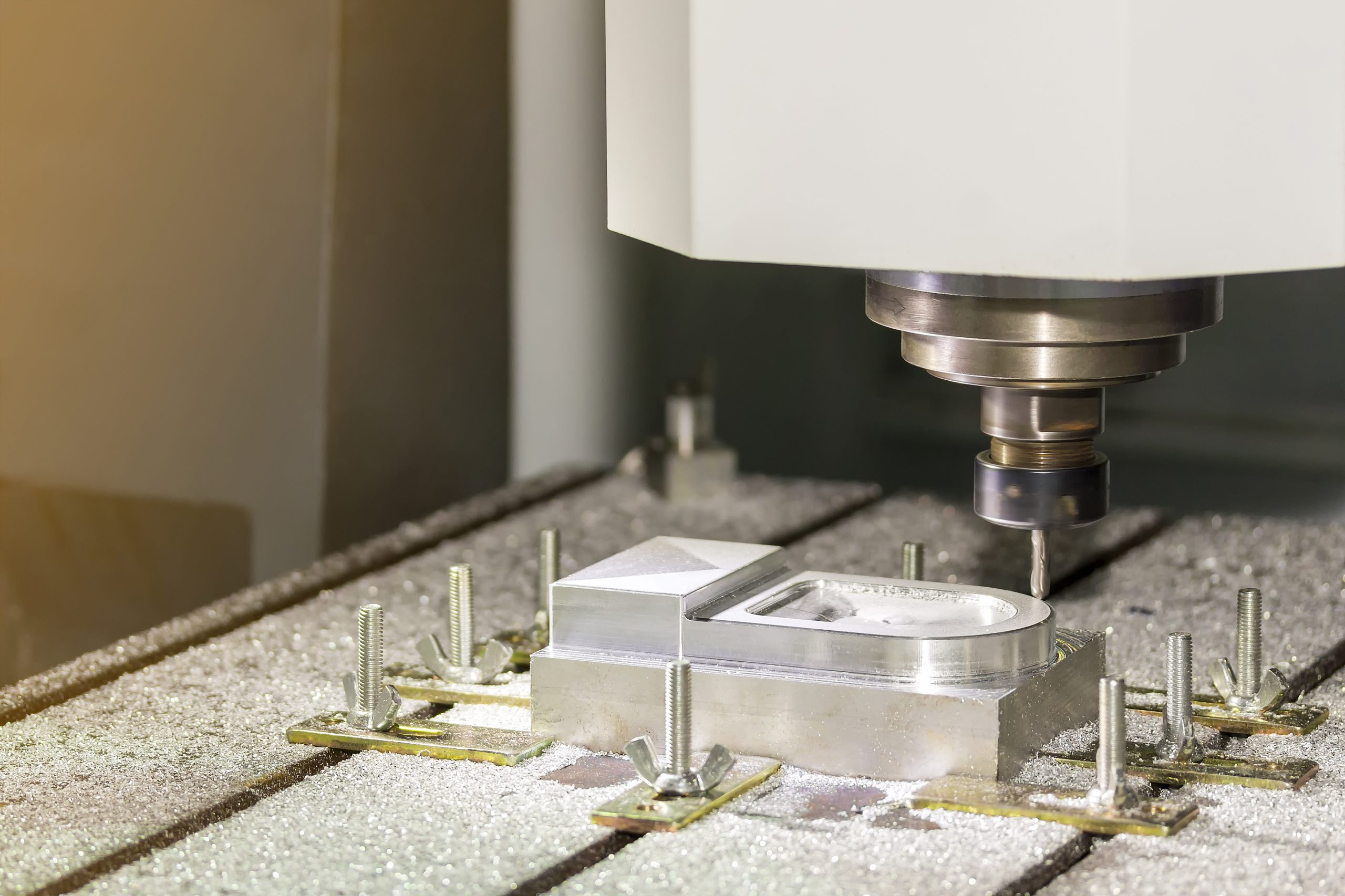

Precision Machining Capabilities that Support Your Production Needs

At Allen Tool, we take pride in offering quality precision machining solutions and outstanding customer service, while ensuring we match your exact needs to bring your vision to life. We specialize in precision machining for the aerospace, defense, and commercial industries, and we continually reinvest in our equipment and technology to bring you cutting-edge innovations in precision machining. For quality machining solutions from an expert manufacturer that won’t sacrifice your budget or your timeline, turn to Allen Tool.