When it comes to consumers, it’s clear that no matter the industry, quality is a top main priority. Quality contributes to customer satisfaction, trust, and brand loyalty, which is conducive to repeat business. In fact, 63% of consumers are happy to spend money on a quality product when compared to a different product that is cheaper in both price and quality. In the manufacturing world, high precision CNC machining is the perfect method for boosting customer satisfaction. It’s the ideal solution for precision machined components because it produces exceptional quality products. Here, we will take a closer look at how the production process enhances quality.

The Precision Machining Process

One of the initial stages of the process involves prototyping because proper preparation is key to crafting high-quality products. Rapid CNC prototyping is used to transform CAD models into quality components, ensuring your precise specifications are met before moving further into the machining process.

Once prototypes are approved, your product can move into the production process. Precision here is important, making high precision CNC machining services, like CNC milling, ideal. Finally, evaluation is a key part of the process that should not be overlooked. A quality precision machining manufacturer will evaluate the finished product to ensure it meets the customer’s exact requirements and performs as expected so that it is ready to be shipped off to market.

A Closer Look at High Precision CNC Machining

There are various manufacturing methods that offer enhanced precision and meticulous attention to detail:

- CNC milling: Using a computer-controlled cutting tool, a CNC milling machine rotates the cutting tool in order to remove material from a workpiece until it reaches its desired dimensions. This method is automated, allowing for more efficient and precise machining, saving you both time and money in the process.

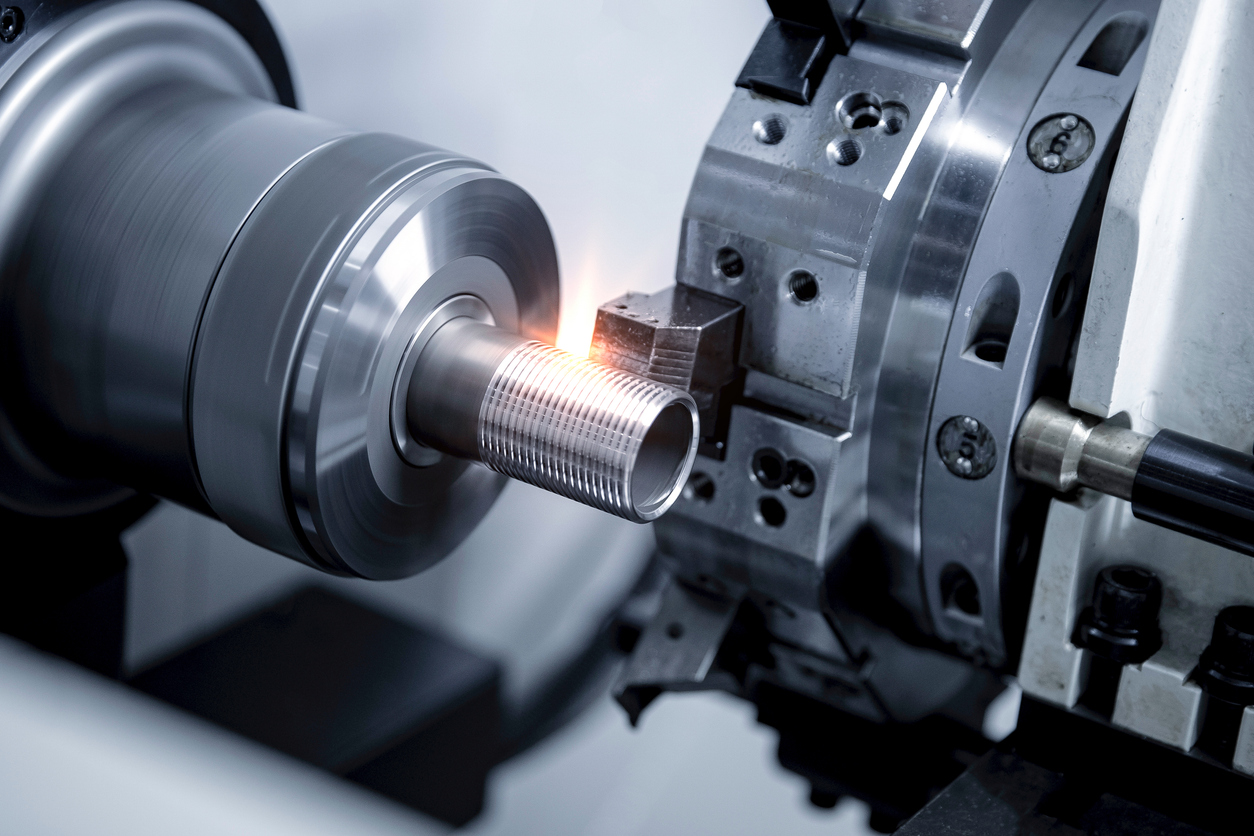

- CNC lathe: Like CNC milling, a CNC lathe is a machining tool that is directed by a computer to remove material. Here, the workpiece is rotated until the desired dimensions are met, and a CNC lathe produces parts that are symmetrical or cylindrical. CNC lathes are versatile manufacturing tools, and can help craft parts with complex geometries, as well as increase precision.

At Allen Tool, we have a number of vertical and horizontal mills, as well as a wide range of CNC lathes. We can work with parts with a maximum CNC milling capacity of 30” x 65” and a maximum CNC turning capacity of 26” diameter x 80” long. No matter how complex, we are able to produce precision machined parts that fit your application.

Partner with Allen Tool for Exceptional Precision Machining Services

In addition to our high precision CNC machining capabilities, we are able to offer rapid prototyping, thread rolling, production machining and more. Precision is built into all of our processes so that your products can achieve the close tolerances and intricate geometries you require. Quality is what we stand for, and we adhere to several essential industry regulations, like AS9100D / ISO 9001:2015, NIST and ITAR. We’re prepared to help you boost the accuracy and reliability of your components. Reach out to Allen Tool today to get started.