In precision machining, durability and accuracy is essential. Components need to be long-lasting in order to perform as required under a variety of conditions, some of which may be harsh or rugged. The thread rolling process is an important method in precision machining that can extend a part’s overall longevity and result in stronger, more durable components. Let’s take a deep dive into the thread rolling process, as well as the benefits this process provides.

If you’d like to enhance the quality of your precision machined parts, turn to Allen Tool. Get in touch with our team today for more information.

A Closer Look at the Process

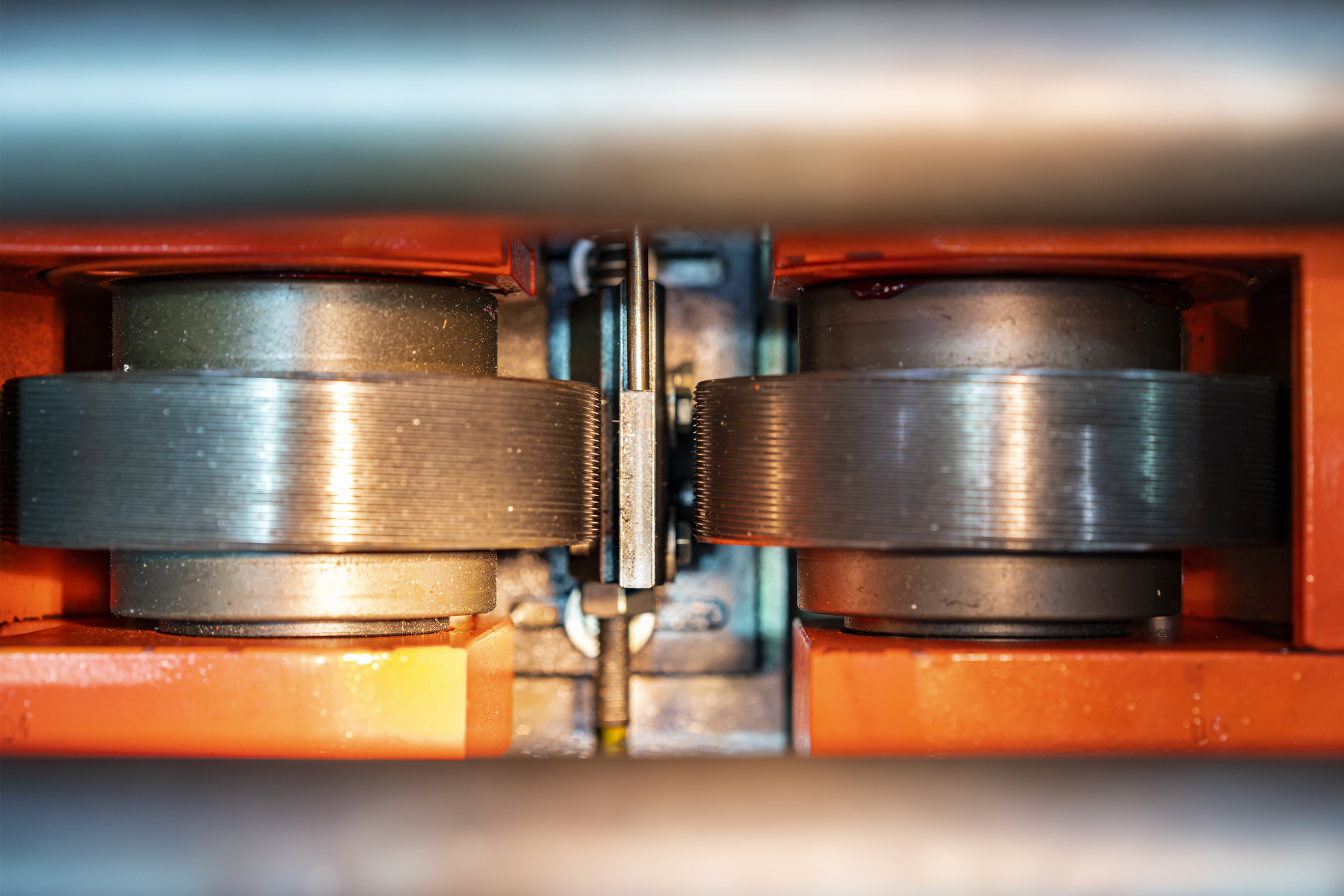

In this process, threads are formed when parts are compressed between two thread dies on a thread rolling machine. The part is machined to a specific stock diameter, which must be precise to allow the right amount of material flow above the original surface. When the part is compressed between the two thread dies, a thread profile is ground into them, and then metal flows into the die cavities.

The thread rolling process is different from other precision machining services, such as grinding. This is a cold-forming process and is not a subtractive process because it does not remove any material to create the desired part. Instead, it displaces materials to produce threads, which results in improved thread strength and overall part performance.

The Benefits of Thread Rolling

Thread rolling is very advantageous and results in higher thread strength in precision machined components. This makes the part more durable and wear-resistant, extending the overall longevity of the part.

In addition to improving a part’s lifespan, thread rolling results in more precision and tighter tolerances. This is essential in highly critical industries like aerospace and defense, which often have unyielding demands. You can also expect improved surface finishes with thread rolling, which can enhance the overall functionality of the part.

Faster than traditional threading machines, thread rolling can result in quicker lead times, making it ideal for high volume production. With the thread rolling process, you can also expect reduced material waste, which in turn lowers costs. Because thread rolling is so efficient and precise, it eliminates the need for costly and time-consuming reworks, ensuring a faster time to market and higher quality parts.

Allen Tool Can Provide High-Quality Thread Rolling Services for Whatever Application You Need

At Allen Tool, we understand that when it comes to precision machining, quality is paramount. For over 30 years, we’ve provided our valued customers with a variety of precision machining services, including thread rolling. With a proven commitment to our customers, we’ve served a wide range of industries, such as aerospace, defense, and commercial.

Our other capabilities include CNC machining, production machining, prototyping and more, and we are well-equipped to provide you with the quality precision machining services that your project requires. At Allen Tool, we’ve perfected the thread rolling process for our customers. To get started on your next project, connect with our team today.